Product Realization

To ensure productivity is maximized and resources are fully utilized, our comprehensive manufacturing process will determine:

- DFM (Design For Manufacturability) Process

- Product End Use, Environmental considerations, Application type, Sizing requirements

- Optimal Functionality, Material type(s)

- Tooling Cavitation driven by Volume and Target Price

Product Realization

To ensure productivity is maximized and resources are fully utilized, our comprehensive manufacturing process will determine:

Design for manufacturability

Product use, environment, application type, sizing requirements

Optimal functionality, material type(s)

Tooling Cavitation will be driven by volume and target price

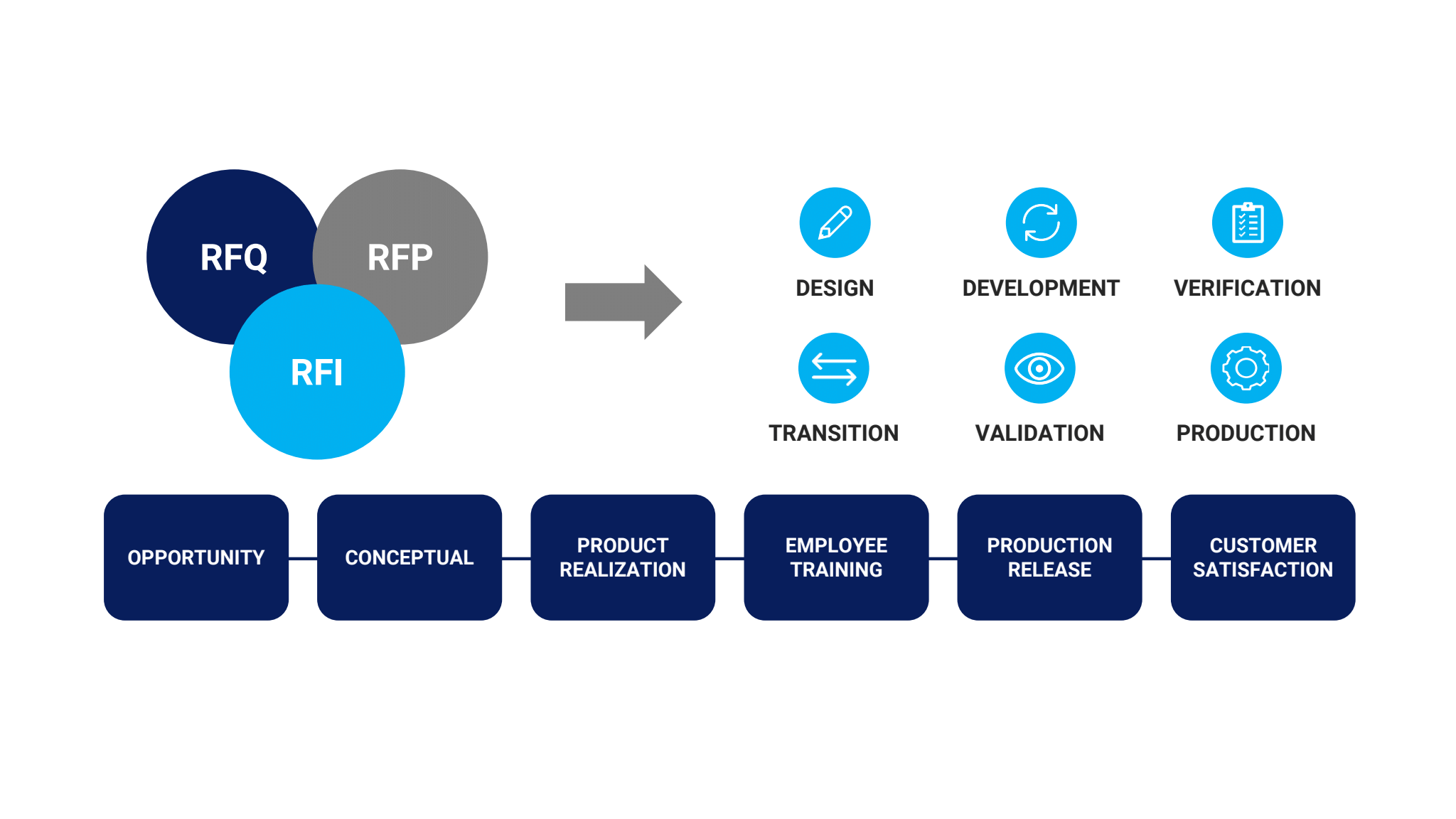

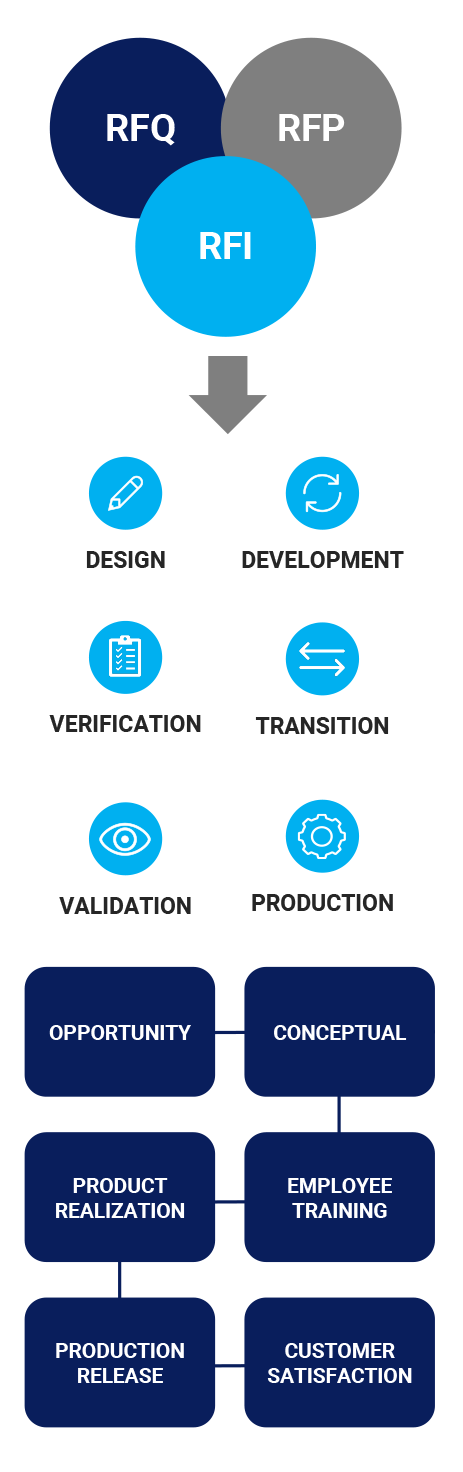

New Product Introduction (NPI)

Once the parameters below have been addressed, we’ll leverage Quality Management Systems (QMS) and Lean Manufacturing to help hit peak levels of efficiency.

Production Systems include:

Just-In-Time (pull system and continuous flow)

Jidoka (built-in quality) & Heijunka (leveled production) applications

Standardized Work (most efficient workflow)

Kaizen (problem-solving for continuous improvement)

Robust quality systems with complete traceability for assurance